Girls in STEAM Electric Car Project 2022 Project Page

(access 2021 project page here)

What is the Girls in STEAM Electric Car Project?

Bendigo Tech School is building an electric car as an aspirational Girls in STEAM community enterprise project to encourage local young women to explore engineering and trades pathways. This exciting project is aligned with our future transport and new energies focus and will start an important narrative for students and the Bendigo Community about the circular economy, future transport, and sustainability.

Over 24 months, the students involved are restoring and converting a Range Rover Classic into a Tesla powered 4WD with guidance from a range of industry partners including Jaunt Motors, the Kangan Automotive Centre of Excellence, and Thales Australia.

The program includes industry tours and visits, guest speakers, practical hands-on activities, talks and workshops with industry mentors and the opportunity to develop automotive knowledge and skills. Girls will also be involved in the project management of the entire initiative.

When complete, the car will be made available for hire, with profits to be re-invested in youth-driven community enterprises and start-ups.

This project was made possible with a 200K donation from Agnico Eagle's Community Partnership Program.

Industry Partners and Sponsors

|

· Kirkland lake Gold · Jaunt Motors · Thales Australia · Kangan TAFE/ACE · Discovery Science and Technology Centre · RACV Solar · Airbag Man |

· JET Charge · Chargefox · Custom and Restoration Services · Bendigo Retro Muscle Cars · Hattam Street Tyre and Mechanical · Famous Four · O’Brien Electrical Bendigo |

August 2022 Update

The middle part of the year has been extremely busy for the EV Project. Our AC Fast Charger has been commissioned and is now availble to the public via the Chargefox network. The Tesla drive unit has been installed into the chassis and custom drive shafts have been fitted. In May we took the the project to the innuagural Trades Fit - Young Women in Trades and Tech expo where we sopke to hundreds of students in years 9-11 about the project and career pathways in the new energies sector.

After a year based at the Discovery Science and Technology Centre workshop, we shifted our base of operations the Custom and Automotive Restoration Services (C.A.R.S) in Kangaroo Flat where we can access expertise needed for the next phase of the project. The car panels were media blasted back to bare metal, and were then meticulously primed, repaired, and painted under the expert guidance of Gary and the paint shop team at Bendigo Retro Mucle Cars. The safety frame has now been reassembled back onto the chassis, and will be displayed at EduTech as part of the Tech Schools stand.

March 2022 Update

During February, the Range Rover chassis arrive back from Jaunt Motors with its freshly engineered electric motor mounts. We reassembled the axles and chassis with help from Hattam Street Tyre and Mechanical, which everyone really enjoyed, particularly packing bearings with grease by hand! Our electric motor has been ordered from Zero EV, and we are now ready to start restoring the body and panels.

There is little repair remaining on the firewall before we send the body frame away to be blasted ready for priming, which we will be doing at Bendigo Retro Muscle Cars. Cola Solar will be installing our charger at Discovery very soon, which will be made available for public EV charging. We are very thankful to sponsors JET Charge for donating the charger, Cola Solar for providing free installation, and Chargefox for giving us a free membership on their charging network.

This project encourages local young women to explore engineering and trades pathways. We have had several new local girls join the program, including our first Bendigo TAFE student! We are looking forward to showing off the hard work of this dedicated group at the Trades Fit Expo for Women in Trades in May along with industry partners Kirkland Lake Gold and Safescape.

Here is a gallery of images showing our progress to date:

|

|

|

| 3D scanning of the engine bay and rear chassis at Jaunt Motors. These CAD files will be used to design the electric motor mounting/placement and battery boxes. | Loading the Rangey for the journey back to Bendigo. |

All secured for the journey... |

|

|

|

| April 2021 - Arrival at BSE. First session with Group A. This is the last time the car will be seen complete for a while. Look at those smiles! |

April 2021 - After a quick induction and tools/fastening briefing, the girls start removing the headlights, grill and indicators. |

April 2021 - Some of those fastenings are stubborn! The girls apply problem-solving techniques to loosen nearly 40 years of corrosion and grime. |

|

|

|

| April 2021 - A hive of activity! The Range Rover Classic is just an outsized Meccano kit. Every part can be unscrewed or unbolted. | May 2021- The Bonnet and external panels are off. Group B facing the tricky challenge of corroded fastenings. | May 2021- Door bolts are proving a challenge, even with a rattle gun and blow torch. Solution - add more WD40 and try again next week! |

|

|

|

| May 2021- At the halfway point and roughly halfway through disassembly. | May 2021- Some of the hardest to access fastenings were the seat bolts...note the slightly unconventional method of removing dash screws. | June 2021 - Moving day! We completed Term 2 at Bendigo South East and have now moved to our new home at the Discovery Science and Technology Centre. |

|

|

|

| June 2021 - All moved into to our beautiful new workspace and ready for the next stage of disassembly. | July 2021 - After undoing every single one of the aluminium roof fastenings with a screwdriver, Del celebrates the moment of liftoff. | July 2021 - Removing more of those pesky fastenings |

|

|

|

| July 2021 - No turning back now...the body frame is completely disassembled ready for rust treatment and restoration. | August 2021 - Rust and bitumen removal from the frame | October 2021 - Quick re-assembly of the engine bay to take data points and measurements for Jaunt Motors to help design battery boxes. Damian from Ballarat TS popped in to help out for the day. |

|

|

|

| October 2021 - Who is that masked welder? Door sill replacement in progress. | November 2021 - Chassis disassembled and rust removal in progress. | January 2022 - Jaunt's Lead fabricator Clive Warner overseeing production of the electric motor mounts. |

|

|

|

| January 2022 - One of two new motor mounts/chassis cross members being fabricated | It's always exciting when boxes of Range Rover parts arrive from the UK! | February 2022 - Packing bearings with grease by hand on location at Hattam Street Tyre and Mechanical |

|

|

|

| February 2022 - Rear Axle Assembly with insruction from Ib from Hattam Street Tyre and Mechanical | February 2022 - Front axle assembly. Many hands make light work. | February 2022 - Close up of front axles showing uprated brake discs and cerakoted axle housing |

|

|

|

| February 2022 - Installing the Boge self-levelling unit to the chassis. We discovered small fingers are best for fitting rubber boot retaining clips! | February 2022 - Close to finishing with our newest recruit Imani, who had dropped into visit her cousins and ended up joining the project. | February 2022 - Presto! - rolling chassis complete and ready for motor and frame fitment. |

|

|

|

| April - After weeks of welding, repairs and frustration, the firewall is finally finished. Della and Charlottre celebrate with a coat of primer. | May - We take the project to The Trades Fit: Young Women in Trades and Tech expo with industry partners RACV Solar, Safescape and Agnico Eagle | May - Our project wins an award from the Tech Diversity Foundation AND the Tesla Drive unit has been installed! |

|

|

|

| June - Della applies epoxy primer to the media blasted panels at Bendigo Retro and Custom Muscle Cars | June - Alan of Bendigo Retro and Custom Muscle Cars gives Della guidance on spray painting | July - Gary of Bendigo Retro and Custom Muscle Cars imparts panel beating secrets to Imani |

|

|

|

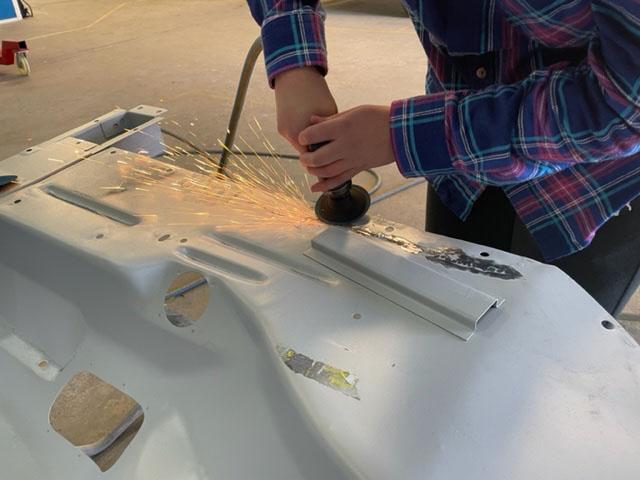

| July - Charlotte grinds down welds to enhance the finish of the floor | July - Unpacking new inner wings from Famous Four in the UK | July - Charlotte applies stone guard to the underside of the main body panels |

|

|

|

| July - Brenton briefs Sophia, Charlotte and Della on the basics of paint prep | July - about to apply colour! | July - wet on wet application of 2 pack (Irish Green - not British Racing Green) |

|

|

|

| Juky - Imani fits the custom prop shafts to the Tesla Model 3 drive unit. (Photo Credit: DET Media Unit) | August - masking up to paint the other side of the frame components | August - Spray booth is loaded and everyone is happy (Photo Credit: DET Media Unit) |

|

|

|

| August - Happy Birthday Imani and Charlotte | August - A light moment during the DET Phot shoot (Photo Credit: DET Media Unit) | August - The body frame is back on the chassis after a year apart |

In the News

We've had a huge amount of media interest in the Girls in STEAM Electric Vehicle Project since we started in March 2021, including a brief spot in Channel 10's Advancing Australia series. Be proud...Bendigo's young people are in the national innovation spotlight!

NGV Melbourne Design Week Project Launch

29 March 2021

This week we held our NGV Melbourne Design Week event 'Building a Tesla powered Range Rover in high school', in partnership with Jaunt Motors.

Attendees had the opportunity to hear about Bendigo Tech School and Jaunt's exciting Girls in STEAM Electric Car Project, in which our Bendigo girls will convert a classic 3-door Range Rover to electric operation.

Students from Bendigo South East College and Crusoe College shared their passion and interest in the project with the audience and gained valuable insight into the electric vehicle conversion process through touring the Jaunt workshop.

We'd like to thank everyone who attended, as well as our special guests: Dave, Marteen and Rob from Jaunt; Doug Peters, who is kindly donating the Range Rover for students to convert; and Felicia Binks from Kirkland Lake Gold's Community Partnership Program who have generously sponsored this project.

We're so excited for this project to get underway! Click to watch a short or a long version of the launch.

International Women’s Day Industry Tour

9 March 2021

This week we celebrated International Women's Day with the launch of our Girls in STEAM Electric Vehicle Project. The kick-off event for this project is pictured above - a local industry tour to highlight some of the automotive, engineering and manufacturing pathways available to young women in our community.

The full-day tour visited two national innovation leaders in Automotive design and manufacturing; Safescape with General Manager Allison Deadman and Thales Australia, with Joshua Di Camillo, Technical & Engineering Director. Along with a visit to Bendigo TAFE to explore the pathways that lead to automotive and manufacturing careers.

The Australian manufacturing industry currently employs over 900,000 people, with women making up 1 in 4 employees. Safescape General Manager Alison Deadman says that industry tours are important to increasing the visibility of the great engineering opportunities in regional Victoria and encouraging young women to pursue these careers.

Girls from Bendigo South East College and Girton were highly engaged, super enthusiatic and asked some really in depth questions. We can't wait to start the EV build with this group.

We visited:

|

Safescape - a specialist provider of safety equipment for the mining industry. They have just started producing the Bortana EV, Developed to face heavy-duty challenges in mining. We visit the factory to find out all about this innovative new electric vehicle.

|

|

Thales Group - a French multinational company that provides services for the aerospace, defence, transportation and security markets. They produce the Hawkei, a light four-wheel drive protected mobility vehicle that delivers class-leading blast and ballistic protection. Thales Bendigo has the only remaining design and build automotive production line in Australia.

|

|

Bendigo TAFE has a has a rich history of providing education for local people and preparing them for work in local jobs. We visit the Bendigo TAFE Automotive and Engineering + Manufacturing departments for some taster activities, including designing a small project for production on advanced manufacturing equipment.

|